What Makes Transformer Oil Regeneration an Industry Must-Have

What Makes Transformer Oil Regeneration an Industry Must-Have

Blog Article

Cost-Effective and Eco-Friendly Transformer Maintenance With Regenerated Oil

The assimilation of restored oil in transformer upkeep offers a compelling strategy for companies seeking to improve both cost-efficiency and eco-friendliness. By utilizing oil that keeps efficiency criteria comparable to virgin choices, companies can substantially minimize functional costs while at the same time reducing their ecological influence.

Comprehending Regenerated Oil

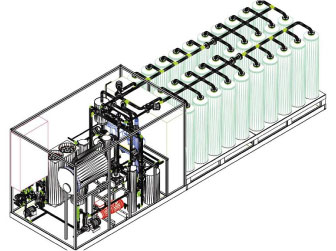

Restored oil, typically described as re-refined oil, is a vital component in the upkeep of transformers, giving both environmental and economic benefits. This oil is stemmed from utilized mineral oils that have gone through an extensive purification procedure, properly removing contaminants and recovering the oil to a top quality similar to virgin oil. The regeneration procedure normally involves numerous phases, consisting of physical separation, chemical treatment, and purification, making sure that contaminations such as sludge, water, and hefty metals are removed.

The usage of restored oil in transformers is essential for enhancing performance and prolonging equipment life expectancy. Top quality re-refined oil preserves its dielectric homes, guaranteeing effective insulation and stopping electric breakdowns. Furthermore, it has excellent thermal conductivity, which assists in managing the functional temperatures of transformers, inevitably improving their reliability and efficiency.

Moreover, adopting regenerated oil not only sustains cost-efficient maintenance strategies but also minimizes the need for new oil manufacturing, thus preserving natural sources. Transitioning to re-refined oil is an intelligent option for companies aiming to maintain high functional standards while all at once taking care of spending plan restraints. Recognizing the buildings and benefits of restored oil is critical for educated decision-making in transformer upkeep methods.

Environmental Advantages

Making use of regenerated oil in transformer maintenance offers substantial ecological benefits that add to lasting practices within the power field. Among the primary advantages is the reduction of waste oil disposal, as regenerated oil is originated from the recycling of used transformer oil, significantly decreasing the volume of contaminated materials generated. This procedure assists alleviate the environmental dangers related to improper disposal approaches, which can cause dirt and water contamination.

Additionally, the regrowth procedure saves all-natural sources by decreasing the demand for brand-new base oil production - Transformer Oil Regeneration. This conservation effort not just minimizes the removal effect on ecosystems however likewise lowers the carbon impact related to oil production. By taking on regrowed oil, business can enhance their commitment to environmental stewardship and align with worldwide sustainability goals

Additionally, the use of regrowed oil enhances the overall efficiency of transformers, bring about decreased energy losses and reduced greenhouse gas emissions. As the power sector progressively deals with stress to decrease its ecological influence, welcoming regrowed oil stands for a positive technique to accomplishing both environmental and functional purposes. In summary, the ecological benefits of making use of regenerated oil are diverse, promoting a much healthier earth while sustaining the power industry's change in the direction of sustainability.

Expense Cost Savings and Efficiency

Making use of regenerated oil in transformer maintenance can lead to substantial cost savings and improved operational effectiveness for energy business. Regrowed oil, produced through sophisticated purification procedures, offers comparable efficiency to new oil read this post here at a fraction of the cost. By recycling oil that would otherwise be thrown out, business can reduce their acquiring expenses while decreasing garbage disposal expenses.

Additionally, the extended life cycle of regenerated oil translates to decreased regularity of oil changes, leading to reduced labor costs and lowered downtime for maintenance tasks. Transformer Oil Regeneration Process. This not only enhances functional effectiveness but additionally allows for an extra structured upkeep timetable, allowing companies to allot resources a lot more successfully

Furthermore, making use of regrowed oil can lead to lower insurance policy premiums as a result of its eco-friendly account. As power business encounter increasing analysis regarding their environmental effect, taking on lasting techniques such as utilizing regrowed oil can reinforce their online reputation and potentially attract investment.

Eventually, the combination of restored oil right into transformer maintenance techniques offers a strategic possibility for energy business to accomplish considerable price financial savings while promoting functional effectiveness, therefore lining up financial efficiency with environmental duty.

Comparison With Standard Oils

While conventional oils have long been the requirement in transformer maintenance, a comprehensive contrast reveals that regenerated oils provide a number of advantages that improve performance and sustainability. Traditional mineral oils, browse this site while effective, usually present environmental dangers, such as contamination and disposal issues. In contrast, regenerated oils are obtained from recycled materials, considerably lowering their eco-friendly impact.

They generally display remarkable oxidative security, which equates to longer service life and lowered frequency of oil changes. This particular not just boosts transformer efficiency yet likewise decreases downtime and maintenance prices.

This quality is vital in keeping transformer performance under differing operational conditions. In general, the advantages of regenerated oils over traditional oils highlight their prospective to change transformer upkeep techniques, offering a more reliable and responsible alternative.

Implementation in Maintenance Practices

As soon as the analysis is full, a customized prepare for transitioning to regenerated oil should be developed, thinking about elements such as compatibility with existing products and functional conditions. Training for upkeep employees is vital, as they need to comprehend the distinct homes of regenerated oils and how to handle look at this now their application efficiently.

Carrying out a rigorous surveillance program will assist in the assessment of efficiency metrics post-implementation, guaranteeing the restored oil meets the called for operational standards. Reclaimed Transformer Oil. Furthermore, developing a regular maintenance timetable will assist in recognizing potential problems early and permit prompt restorative activities

Conclusion

To conclude, the fostering of regenerated oil for transformer maintenance offers a viable service that lines up financial benefits with environmental sustainability. By minimizing prices connected with oil adjustments and waste disposal, while concurrently expanding the lifespan of equipment, organizations can improve functional performance. The change to regenerated oil not only reduces ecological influences yet also supports broader sustainability goals, making it a prudent option for contemporary upkeep techniques in the power field.

Restored oil, often referred to as re-refined oil, is a crucial element in the upkeep of transformers, supplying both ecological and financial benefits. This oil is derived from used mineral oils that have undergone a comprehensive purification procedure, properly getting rid of impurities and recovering the oil to a top quality similar to virgin oil.Additionally, embracing regrowed oil not only sustains cost-efficient upkeep methods however also reduces the demand for brand-new oil manufacturing, thus saving natural sources. One of the key benefits is the decrease of waste oil disposal, as regenerated oil is derived from the recycling of used transformer oil, substantially reducing the volume of harmful waste generated. Regrowed oil, created through innovative filtration processes, offers equivalent performance to brand-new oil at a fraction of the cost.

Report this page